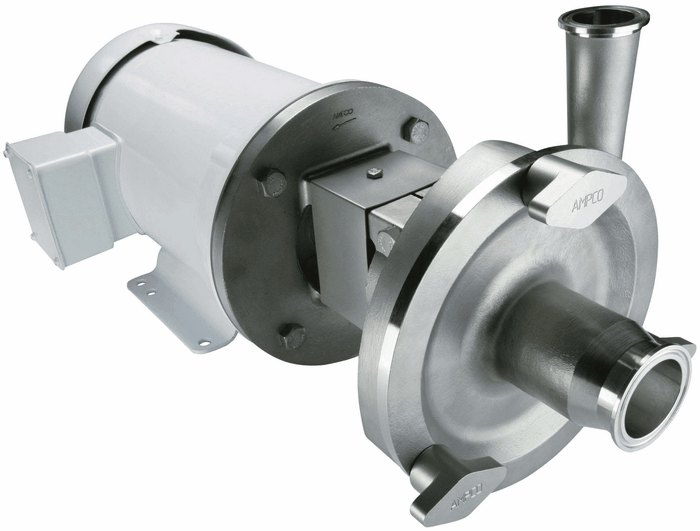

Sanitary Pump for Better Efficiency

There are few centrifugal types of sanitary pumps available that can be used for transferring any fluid from one place to the other. The kinetic energy that is stored in the motor is used for moving the liquids.

Basic function of such sanitary pumps is to move the liquids at any pre-determined force or speed. There are certain categories of such pumps where its every component can be disassembled and cleaned separately to make them free from any contamination.

Most of these pumps find application in pumping those liquids at moderate pressure whose viscosity is low. Also, those liquids that contain any suspended solid particle can also be easily handled by these pumps.

Therefore, mostly these pumps can be used for dairy and many other food industries where cleanliness is very important criteria in the production line. Focus usually remains for low viscosity liquid however it can also handle any heavily aerated liquids too.

How does it work?

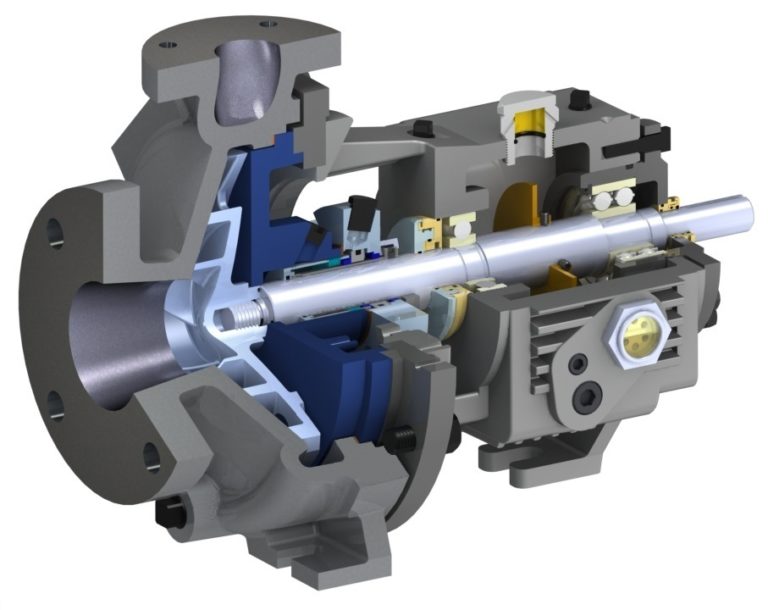

It basically consists of impeller which is a wheel carrying vanes that usually revolves in the outer enclosure which is known as casing. Liquid will first enter in the pump from the center which is called its eye, that discharges in tangential manner.

Due to its angular velocity, which is produced by the impeller the pressure is created which is subsequently transformed in the head of the casing of the pump.

Therefore, the efficiency of the pump will largely depend upon the design of its casing. Cavitation will generally occur when pressure in its suction line becomes too low in comparison with the vapor pressure of the liquid which is pumped.

Cavitation will result in reduced head and due to lesser efficiency.

Salient features

- Smooth even flow

- Sanitary design

- Economical and flexible speed design

- Compact size

- Vibration and noise free operation

- Lower maintenance cost

- Easier to control

- Easier control of rate of flow by using valves in the line of discharge

- Lighter gross weight

Various applications:

- Fire protection, heating or ventilation system, pressure boosting and sprinkler systems

- Processes in air conditioning

- Power plants, oil and energy producing companies

- Municipal civic operations e.g. drainage or flood protection, plants for waste water treatment

- For chemical, pharmaceutical industries, process industries, sugar refining, cellulose, food and beverage productions etc.

- Cryogenics and refrigerants

There are number of companies that can offer such sanitary pumps of centrifugal type and they cater the need of various food and beverage industries. These pumps can be adapted to any kind of manufacturing conditions.